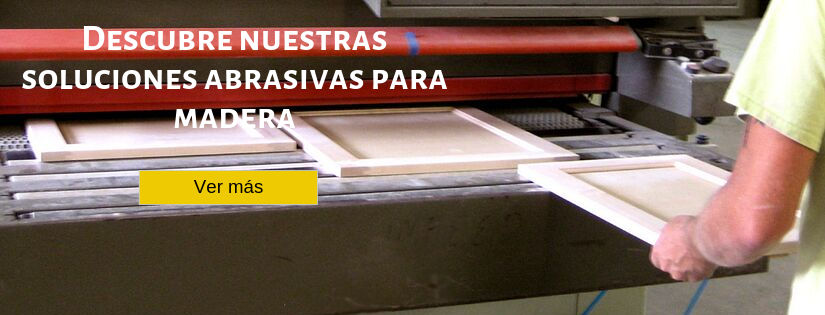

El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}Conquer the customer is the maxim of all companies that want to sell their products. For this, furniture manufacturers strive to offer innovative, more attractive designs with new functionalities that add value and distinction. They provide the user with the freedom to configure their own compositions and be able to customize textures, colors, finishes ...

The new applications in today's surface coatings, the combination of different materials and the variety of surprising finishes made have a meeting point: “the need to carry out a precise, technical and demanding sanding that allows us to achieve the perfection of the surfaces "

In this post, we want to focus our attention on the high value that sanding provides in order to achieve a surface with an excellent finish and discover why in terms of sanding it is important to work with a specialist manufacturer supplier.

1. You will find the professional solution you need.

From the point of view of sanding, the treatment of surfaces and finishes are becoming more precise every day, in which new materials appear to be treated and require the necessary technique.

At the manufacturing level, we seek efficiency, minimal processing, achieving the finish in the shortest possible time and in the most comfortable, practical and safe way for the operator, being respectful with the environment.

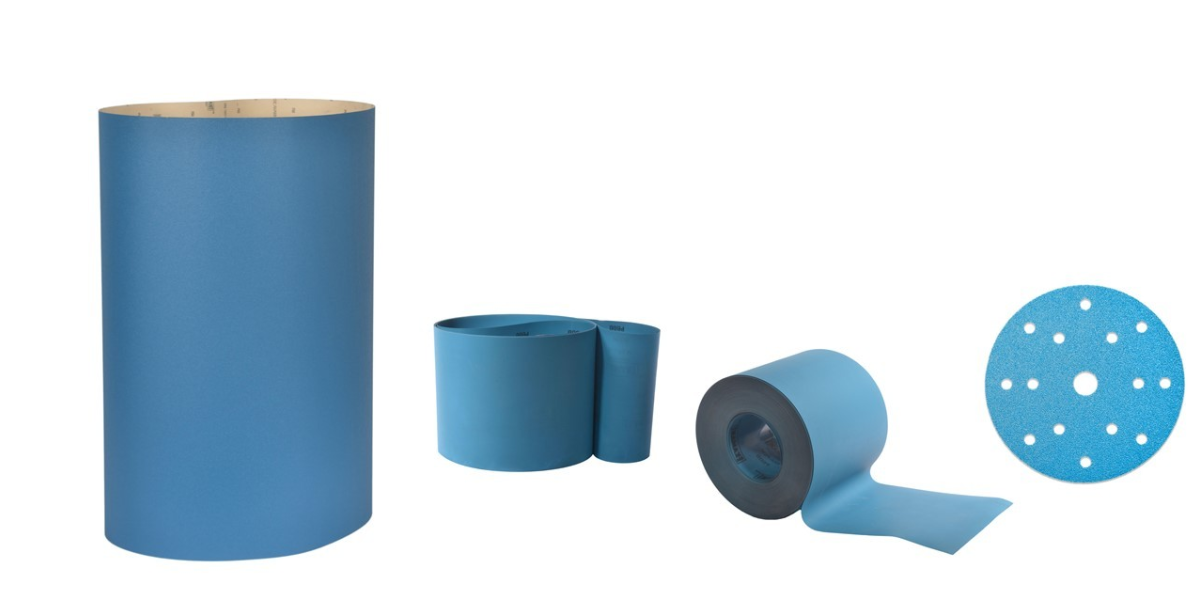

The specialist abrasive manufacturer is a one-stop-shop. It has a full range of solutions to cover sanding needs: abrasives, machinery and accessories necessary for the correct treatment and finishing of surfaces.

In its range of abrasives, it has several options so that the user can choose between abrasive belts with high performance with competitive prices, and standard abrasive belts with low prices.

2. You will have a fast and flexible manufacturing service.

In the industrial sectors, the applications with abrasives are very diverse, and there is a huge range of types used: cutting and grinding discs, sanding discs, fiber brushes, sheets, sponges, rolls, belts, grinding wheels, diamond discs, brushes wire, carbide burs, superabrasives...

The vast majority of these abrasives are finished products, which do not require transformation, and which can be supplied immediately by the supplier companies in each sector.

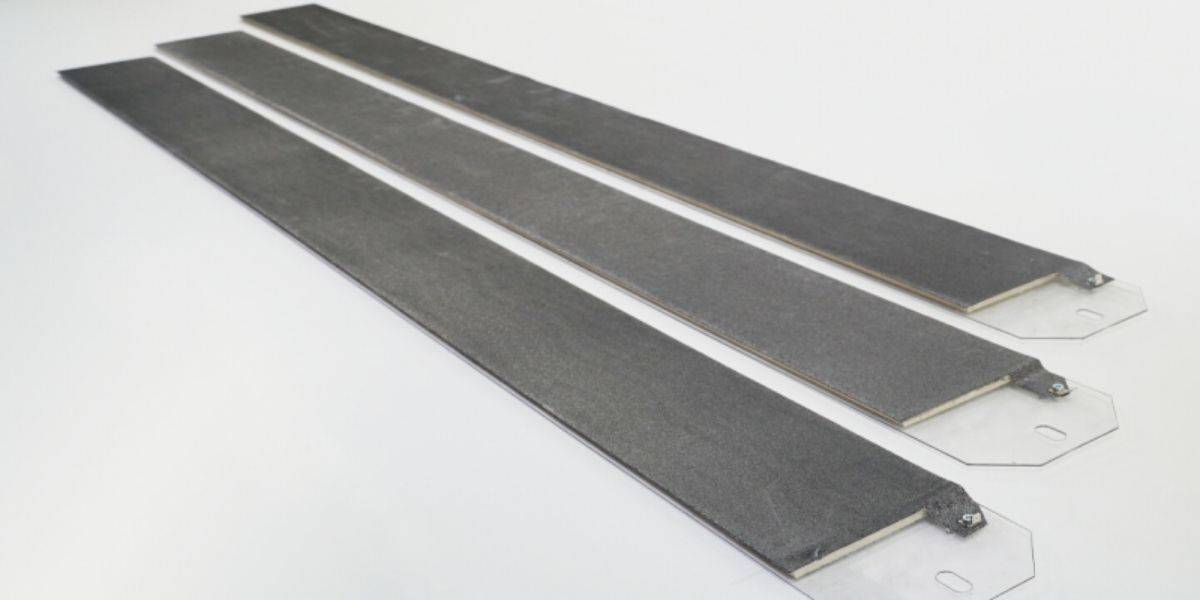

However, abrasive belts are products that are tailored to the needs of each manufacturer. In a sanding belt the combinations of width and length are almost infinite, belts from 6 mm wide to 2,350 mm are manufactured in innumerable developments.

Furthermore, dimensions are not the only factor that precludes an immediate supply of abrasive belts. Each type of material requires a specific abrasive mineral and a suitable type of support that adapts to the conditions and demands of the job. Similarly, the size of the abrasive grain is another variable that has a multiplier effect on the options required.

All these conditions make the delivery times by the distribution companies lengthen, as they cannot stock the belts and have to request them from their usual supplier, who generally, as they are international brands, do not manufacture in Spain.

The manufacturer-transformer of abrasive belts controls all these variables, they are the day-to-day of your business. It is a true specialist in this type of abrasive, which, unlike its competitors that do not transform, can manufacture and serve your orders in a few days, offering fast service and being able to attend to the emergencies and setbacks that every industry has in its daily activity.

3. You will benefit from direct factory prices, without intermediaries.

In industry, the purchase of abrasives through supplies, distributors and small resellers is common practice; And being able to buy directly from the manufacturer-transformer of the belts provides important advantages both in the delivery time and in the final price of the products.

Today, specialist sanding belt manufacturers have adapted their manufacturing processes to the needs of their customers, and are flexible at all levels of consumption, being able to manufacture from small quantities to large orders of abrasive belts.

4. You will get the qualified advice you need.

Design, innovation and the use of new materials prevail in these times, and to conquer the consumer, the offer of finishes on surfaces is key.

Sanding applications are the previous step to any surface treatment or finish; and having the specific abrasive is not enough. We must know and master the sanding technique to be able to achieve the expected result in the shortest possible time, to be efficient and avoid surface imperfections as a result of excessive exposure time.

In this sense, the qualified belt manufacturer is a specialist in its sector and can help us to achieve the desired finish, avoiding unnecessary costs and time.

5. You will have the guarantees and after-sales support when necessary.

In the day-to-day life of a factory, anomalies and problems arise to solve; And having the direct help of the manufacturer is an important value.

The manufacturers of abrasive belts are no exception and offer their customers security and guarantee in their purchases, helping to correct the problems in which sanding belts can be immersed.

At Abracom we are abrasive manufacturers-transformers with more than 35 years of experience in the sector. We have new high-precision machinery to manufacture any type of belt and we make all types of joints used in different industries. We manufacture the sanding belts, according to the needs of each client, within a maximum period of 48 hours.

We are a specialist supplier and we have qualified technicians to advise our clients and help them achieve the finish they want. Contact us for more information.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)