El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}In the same way, there is a wide range of materials to be treated, from carbon steels, stainless steels, aluminum, composites, gelcoat, wood, varnish, plastic, lacquers, glass ... All of them with different physical properties and characteristics, which make it necessary to have of an extensive range of abrasive discs for proper treatment and finishing.

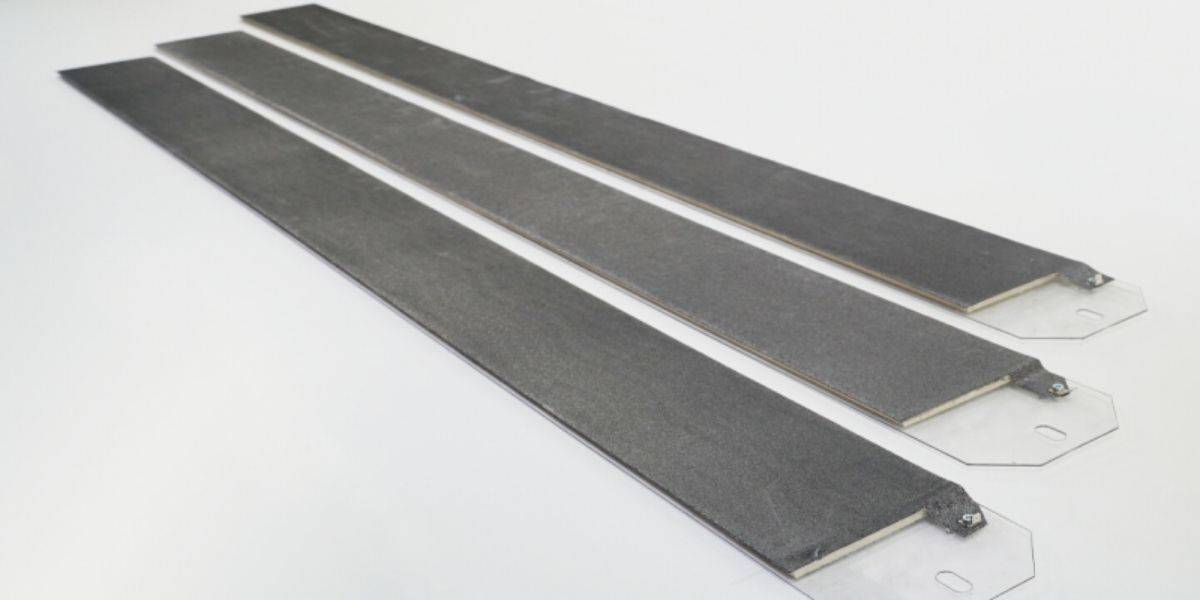

In this article we are going to focus on those manual applications that are carried out by using portable rotorbital machines; and in particular to learn more about flexible abrasive discs and the importance of their supports.

But first, it would be convenient to have an overview of the majority of abrasive discs on the market based on:

Type of operation they carry out.

Clamping system to the machine plate.

Type of media of the disc itself.

What abrasive discs are used for each application?

Below, and although each manufacturer has its own criteria, a classification of the different abrasive discs (without shaft) on the market is shown. As can be seen, the options available for surface preparation work are very varied.

Cutting and roughing applications

Depressed center cut-off wheels

Flat cut discs

Grinding discs

Flexible grinding discs

Coarse, intermediate, fine and clean sanding applications

Fiber discs

Conical flap discs

Flat flap discs

Flexible media discs for paper, film, foam, ... with velcro fastening

Non-woven fiber discs for tinting (scotch)

Surface conditioning discs

Discs with roloc support

Clean & strip cleaning discs

Unitized eraser discs

Applications for a high gloss technical finish

Discs with micro replicated pyramidal mineral

Microabrasive discs

What are the most common abrasive disc attachment systems?

Another aspect to take into account when identifying the different abrasive discs is the type of attachment or attachment to the machine plate.

In the market we find four main fastening systems:

Discs without an apparent fixing system on the support side.

These discs have a central hole that is placed on the threaded shaft of the machine. It is then fixed using a clamping thread. They are used in angle grinders primarily intended for roughing or rough sanding of metals.

Discs with a velcro fastening system.

There are two types: without central hole for angle grinding machines and / or orbital sanders; and center hole discs for self-centering angle grinders.

Roloc system discs for use in angle grinders.

Self-adhesive mounting discs for orbital sanders.

What are the most common abrasive disc holders?

The type of support is the most influential element when defining the performance of the abrasive disc. In general, the work to be carried out and the surfaces to be treated are very varied, and require different degrees of rigidity and / or flexibility in the abrasive support. At other times, supports are required to facilitate dust aspiration. In finishing and tinting operations, the foam supports achieve better finishes thanks to the cushioning during sanding. The main supports on which abrasive discs are manufactured are:

Metallic.

Made of vulcanized fiber.

Of paper with different weights.

Polyester film

Crosslinked polyamide mesh.

Paper with foam.

Sponge

Non-woven fiber

Stiff fabric

Next, we are going to analyze in more detail flexible abrasive discs, which can perform the following functions:

As a further step in roughing work.

As a previous step to the finishing work.

Simply for intermediate or fine sanding of the surface.

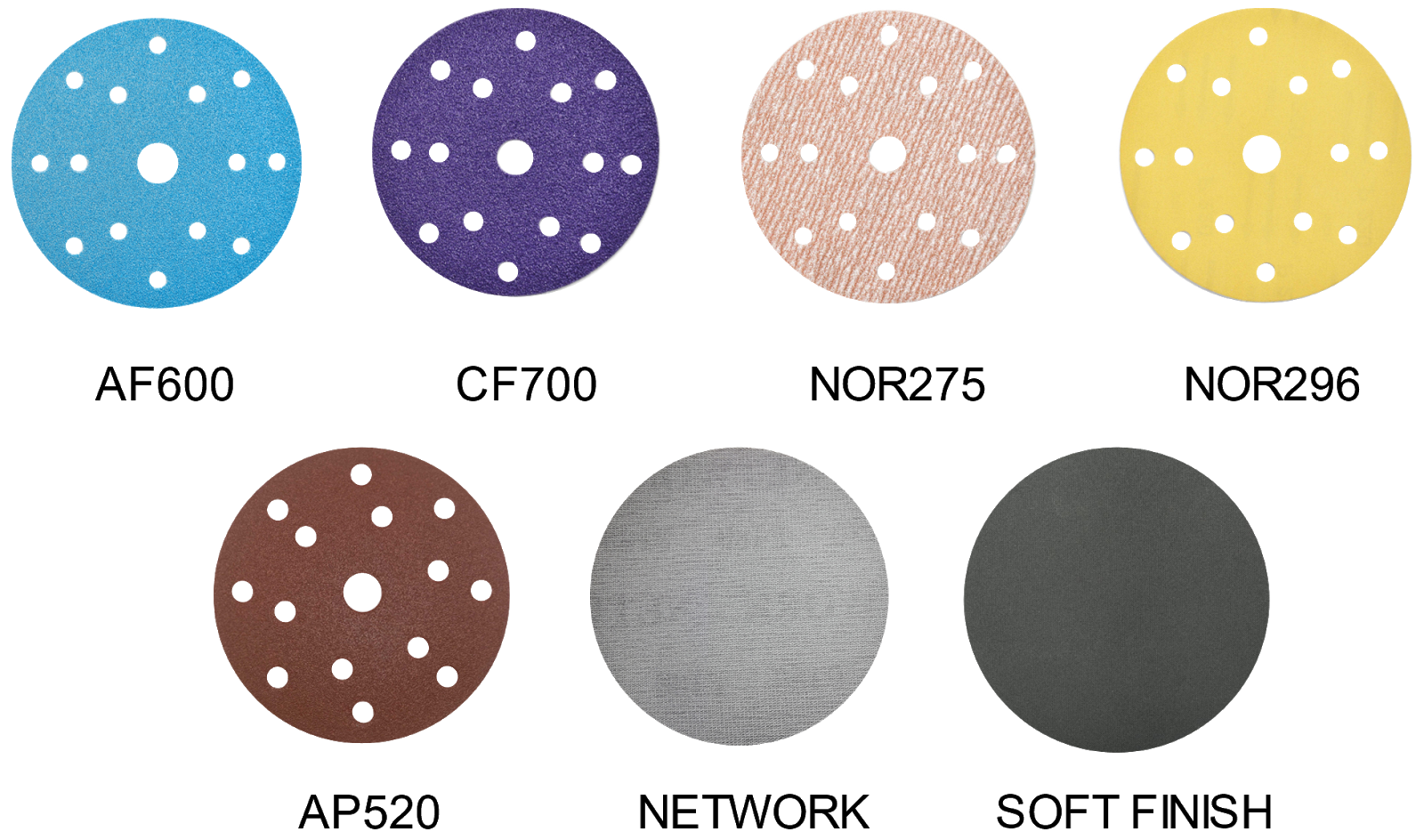

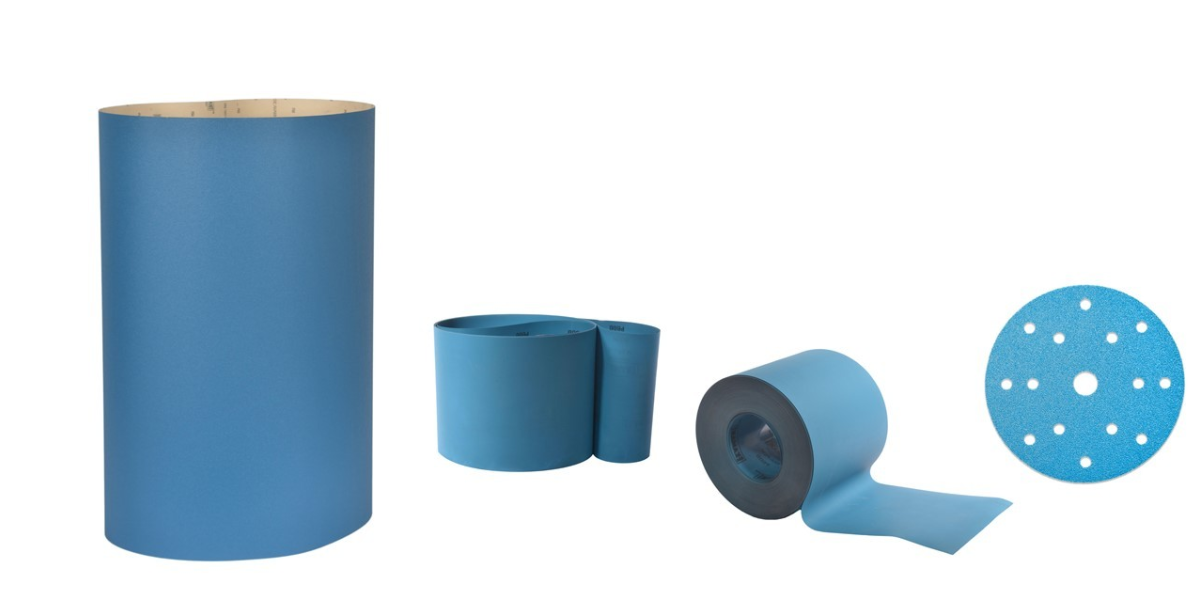

What flexible abrasive discs can we find at Abracom?

WITH POLYESTER FILM SUPPORT

AF600 is a highly versatile abrasive disc, which perfectly combines optimal aggressiveness on coarse grains with a high level of finish on finer grains. The product has a high resistance to heat. The disc support is made of a thin sheet of strong, flexible polyester film. This sheet, unlike paper supports, has a uniform thickness generating a completely smooth surface. The influence of the substrate on sanding operations is very high, since it allows to plan the surfaces sanded with coarse grains and at the same time generates very uniform finishes in the finest grains, thanks to the perfect alignment of the thousands of abrasive minerals anchored on its support.

CF700 is a disc designed for the most aggressive sanding. Its support is made of a reinforced film polyester sheet, which makes it a resistant product suitable for any sanding operation with coarse grains. It stands out for its high starting capacity and performance, thanks to the perfect combination of its ceramic minerals with a stable and resistant support.

WITH POLYAMIDE MESH SUPPORT

NETWORK is a next-generation abrasive designed for dust-free sanding. It is a very versatile product that can be used on almost all surfaces. The high efficiency of the aspiration is achieved thanks to its polyamide fabric support as a reticulated mesh, with thousands of holes that allow the passage of air and sanding dust.

The filaments of the polyamide mesh are impregnated with thousands of abrasive minerals that facilitate a uniform sanding pattern and a totally smooth surface.

Thanks to its great capacity to eliminate suspended dust, the quality of the work environment is improved.

WITH PAPER SUPPORT

NOR275 has been designed for the most demanding finishes. It has a high-quality flexible latex paper backing. Its support is much more flexible, uniform and smooth than other paper-based abrasives. Its abrasive minerals are covered by an anti-slip stearate layer that gives it resistance to clogging and allows it to produce fine surface finishes. Thanks to the latex of its paper, it can be used in both dry and wet sanding applications.

NOR296 is a multipurpose abrasive. It is made on a flexible paper backing, weight B, reinforced with latex, which makes it an ideal abrasive for fast and aggressive sanding. Its minerals are reinforced by an anti-slip stearate layer that helps prevent clogging and slow clogging.

AP520 is an abrasive with an optimal level of aggressiveness. Its support is made up of a strong, semi-rigid, E-weight paper of about 250 gr/m². It has good behavior against elongation. Thanks to the resistance of its support it allows us to achieve a quick removal of residues, especially in sanding operations with coarse and medium grains.

WITH FOAM SUPPORT

SOFT FINISH is a foam-backed disk for versatile sanding, designed for flexible sanding of all types of surfaces, both smooth and profiled. Thanks to its cushioning action, it facilitates smooth sanding at angles and edges, reducing the risk of marks or peeling due to excess pressure.

Both its foam backing and the flexible fabric impregnated with abrasive minerals on the upper part facilitate the passage of air and water. This makes it an ideal product for both dry and wet sanding.

At Abracom we are specialists in surface treatment. We have the right abrasive for every material and sanding application. We have all the most common diameters and a number of holes since we punch the discs in our facilities.

Contact us and we will advise you on the abrasive disc that best suits your sanding needs.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)