El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}The concept of transformation of substrates What does it consist of?

Today, these surface preparation works have given way to a transformation of substrates into new products that remind us of natural materials, outdoor spaces and nature, allowing a connection between the human being and his environment.

This transformation allows us to enjoy environments and surfaces that provide a balance against the lack of natural sensations generated by the digital age, machines and new technologies.

New opportunities in the market

To achieve this transformation of the substrates, companies have innovated to achieve new surfaces, with different shapes, reliefs and textures; creating trends and promoting the use of new products far from the classics.

These new substrates combine a wide range of different and varied materials:

Marbles, stones and cements.

Metals and iron

Plastic and PVC

Wood and veneer

Solid surface

Cork and paper

They are looking for surfaces with tactile textures, reliefs, marked and open pores; as well as all kinds of textures and gradients. Colors drift towards darker tones, moving away from white and light surfaces inherited from the Nordic trend of recent years.

As for the finishes, unlike what happened in recent years, they move away from opaque lacquers and pursue a natural appearance that visualizes the value of the substrate. For this, colorless matt or super matt finishes are used.

Monochromatic decoration with white as the main axis has given way to more colorful surfaces that combine different types of materials and that integrate the different spaces of the home. The combination of wood substrates with materials such as stone and marble tries to highlight the imperfections so that the raw materials shine.

On the other hand, metals and glass combine perfectly with wood, providing design solutions. Metallic finishes are reproduced with a burnished, polished and nuanced effect that combines with the rest of the set.

Innovation in surfaces, a key element in the transformation of substrates

Furniture manufacturers are evolving through innovation in surfaces, adapting ideas and designs of the latest trends to their furniture; providing novelty and differentiation to its customers.

Manufacturing is adapting to short production series, to tailor-made suits resulting from the customization of projects derived from habitat and contract channels.

To achieve this innovation, companies must have specialized machinery for surface treatment, such as varnishing lines, drying tunnels, sanders or digital printers. That is, complete solutions for laminating, coating, varnishing or printing different types of surfaces.

New technologies as a result of the transformation of substrates

In recent years, manufacturers of machinery for surface treatment have developed new technologies, capable of achieving new finishes and movement effects on surfaces; and thus satisfy a demand that is increasingly willing to change rapidly towards the new.

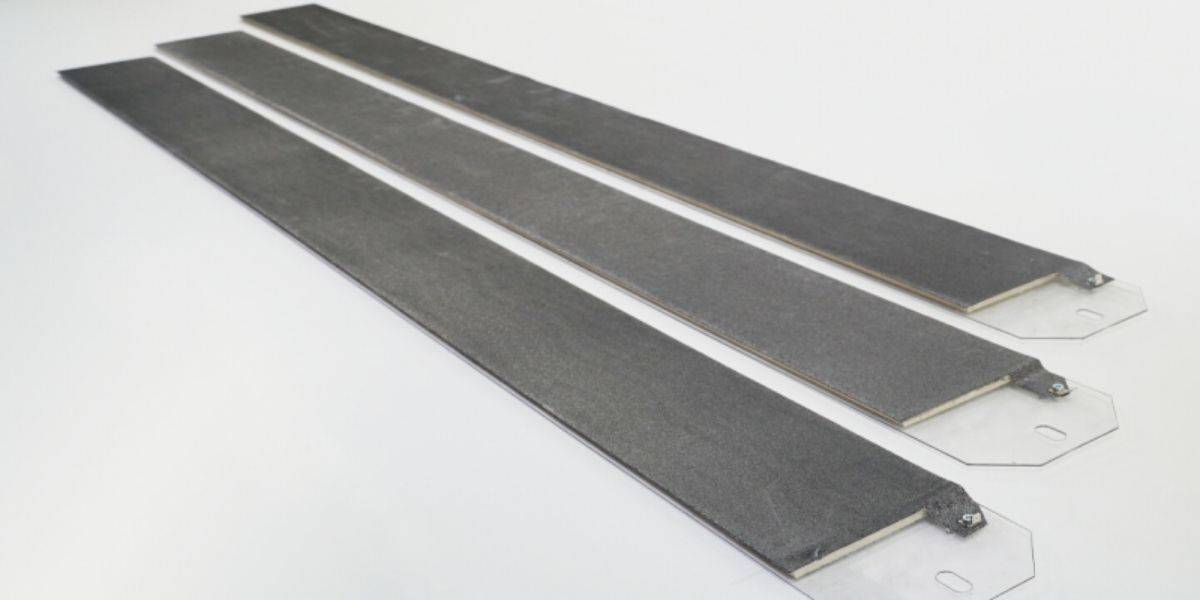

Manufacturers for surface treatment have developed new technologies for sanding processes, in flat pieces, edges and 3D pieces, capable of creating textures and effects unthinkable a few years ago.

The new sanding machines or stations combine different groups: transverse and longitudinal sanding units and brushes that incorporate a technology that allows the transmission of the necessary sanding pressure and time instructions in milliseconds in each unit, in order to reproduce an effect on the sanded piece or another.

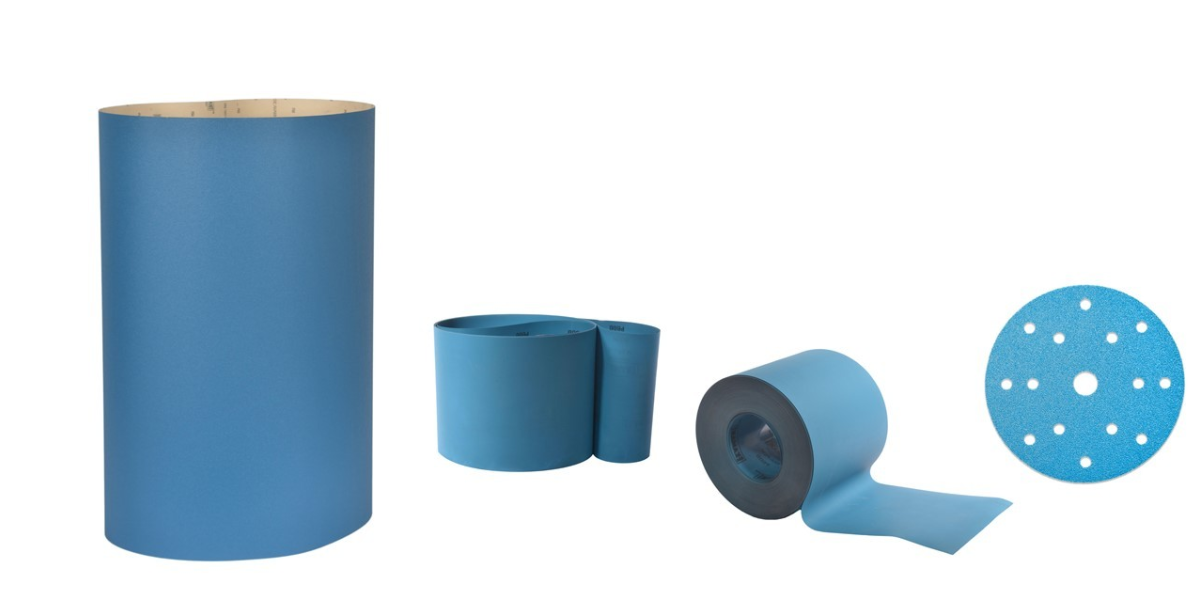

Abrasive belts: an essential for surface treatment

Abrasive belts, used in sanding operations, become a key element to achieve new surfaces and more attractive finishes.

The sanding concept has evolved from the basic functionalities, from planning and creating anchor points and providing a uniform roughness to the surface, to being the generator of different shapes and effects.

Thanks to new technologies in machinery and abrasive belts for the industry we can achieve different effects:

Saw cut effect.

Vintage or stripped effect.

Relief effect.

Graffiti effect.

Stone effect.

Savanna effect.

At Abracom, we not only have the most suitable abrasive solutions to achieve these effects, but also the technical knowledge and experience necessary to do so successfully.

Do you need more information about our products? Do not hesitate in contacting us, we will solve all your doubts.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)