El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

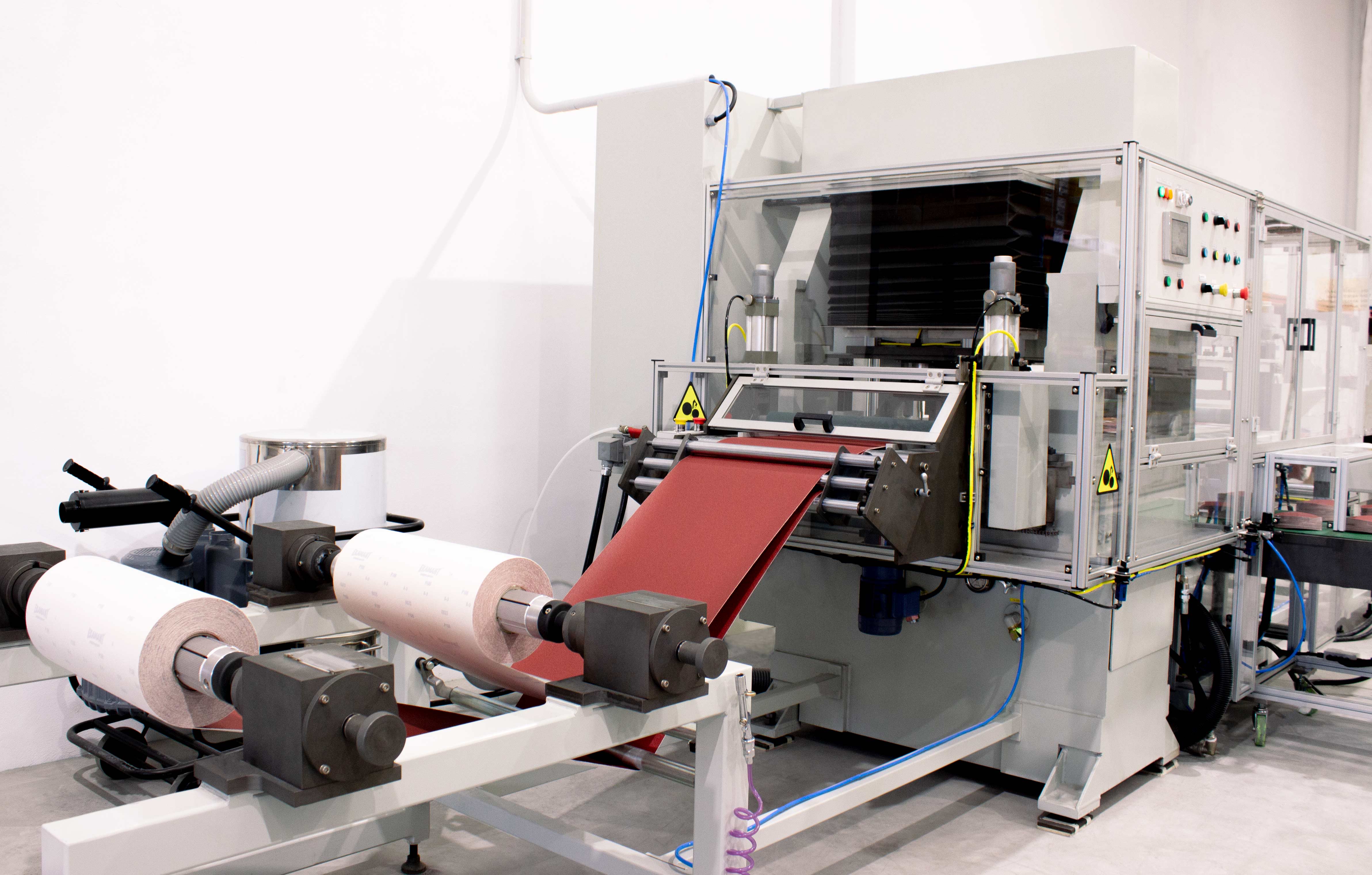

}At Abracom we have acquired a new automatic die cutting machine for the production of abrasive discs and sheets at high speed.

The main advantage of this machine is great flexibility and a high working speed to be able to face all kinds of orders, with a great variation in formats and sizes.

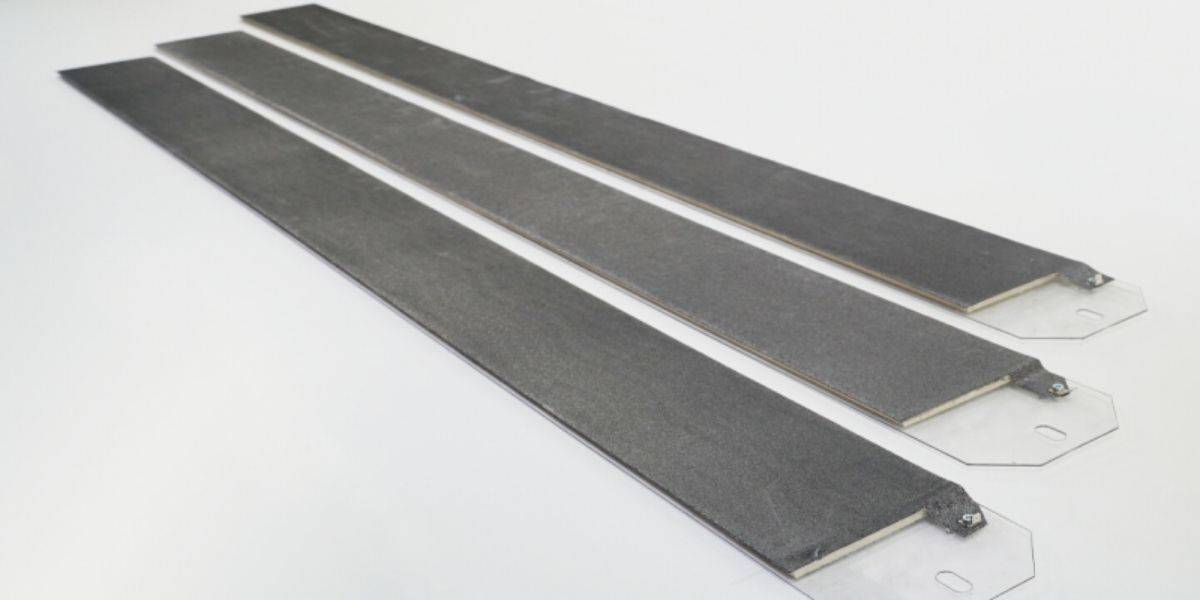

The die-cutting of abrasive discs and sheets covers industrial sectors as diverse as: automotive, aeronautics, nautical, composites, metal, wood and varnishing, painting and decoration, construction, etc...

These consumables, intended for mass consumption and with such a wide field of application, are in high demand by manufacturers and users in different industries.

Advantages of the new abrasive disc die cutter

The main advantage of this new die-cutter is its autonomy throughout the entire process, not only in the operation of punching the discs and sheets, but also because it has an automatic system for stacking discs/sheets after cutting and the possibility of preselecting the number of units to be stacked to be packed later. This function reduces the number of operators required for these operations.

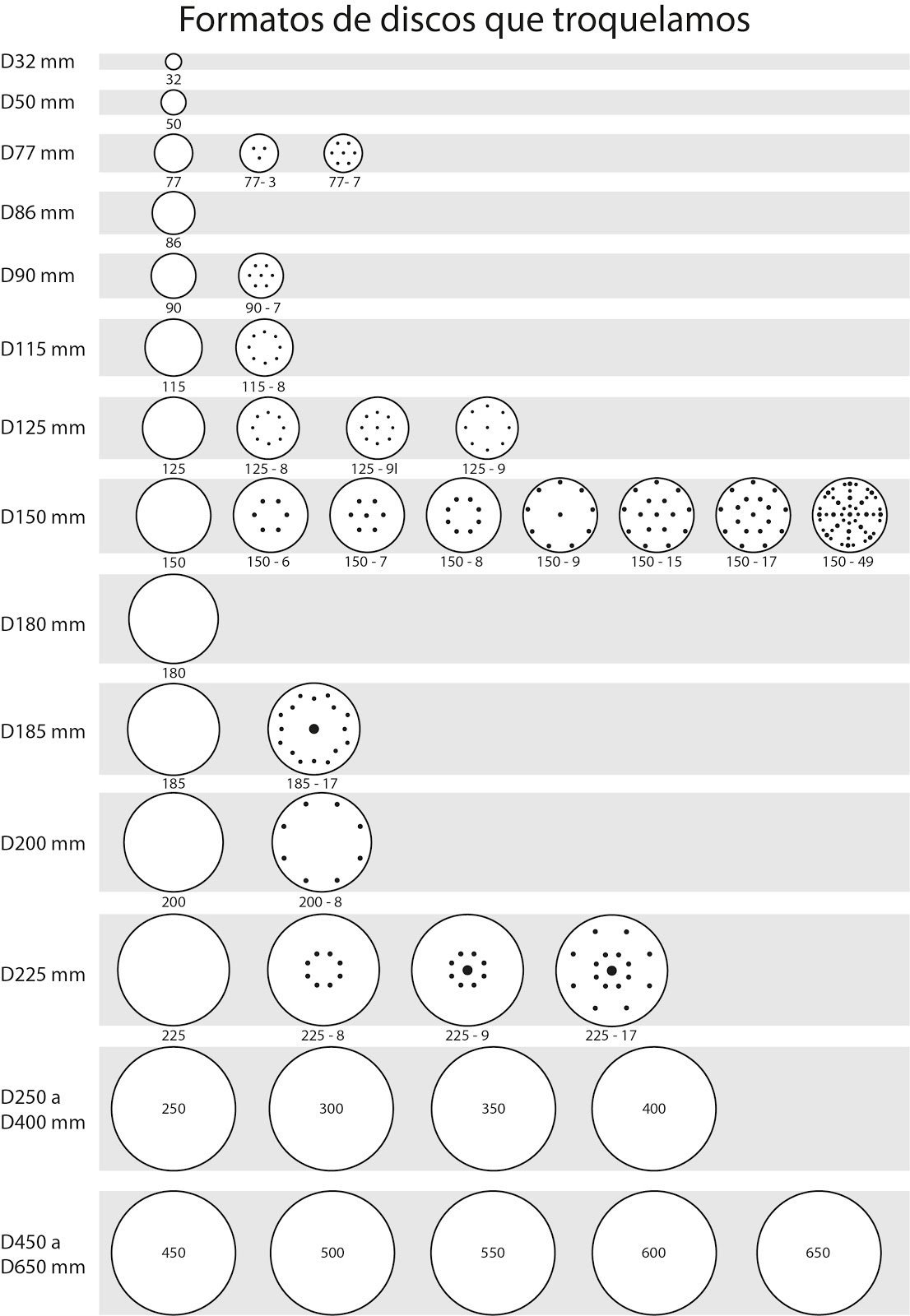

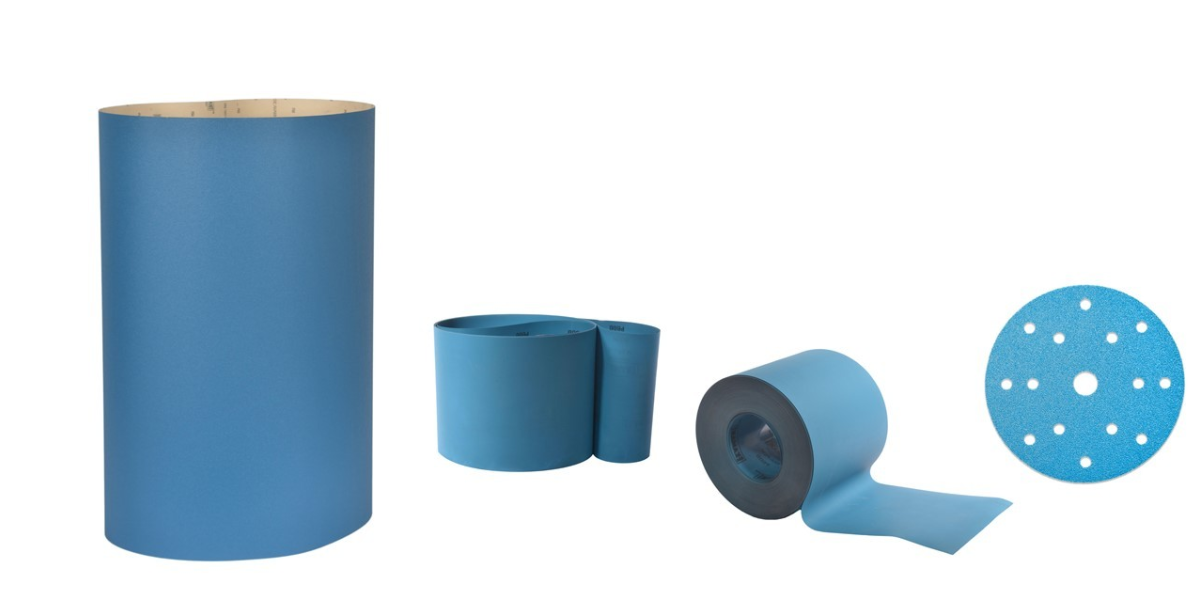

In recent years, abrasive discs and sheets have evolved into models with a greater number of holes for greater suction capacity. We must consider that the useful life of these abrasives depends, among other factors, on the suction capacity during sanding work. The greater the dust aspiration, the less clogging will be suffered by the abrasive mineral that generates it.

In the new die-cutter, both the size control system, as well as the number of holes or their arrangement, is easily carried out by means of a PC with memory for more than 100 cutting programs. At present, at Abracom we have more than 75 different formats between disc models and abrasive sheet models for the different types of existing orbital and rotorbital sanders.

Manufacturers of rotary and orbital sanders look to the efficiency of the suction systems of their machines, a way of differentiation. An example is the 150 mm diameter abrasive discs, which have evolved from the initial 6-hole models, through the 15 and 21-hole models, to the current multi-air systems with more than 170 holes per disc.

For punching of holes with a clean-cut and maximum precision, the new punching machine incorporates an automatic compensation system for the wear that the punch suffers during the cutting process.

In search of differentiation

Every year, the machine tool market looks for new systems on which to base its commercial and promotional strategy. This dizzying search for differentiation means that every year there are a greater number of different formats on the market, in terms of abrasive discs and sheets.

For this reason, from Abracom, as a specialist company in sanding with abrasive discs and sheets for different industries, we have invested in strengthening the die-cutting plant that we currently have.

This new machine is added to the two already existing die-cutter machines; which has, among other advantages, a quick and easy system for placing raw material rolls and changing dies, which allows us to increase productivity and further shorten delivery times; as well as reducing the number of minimum units to be manufactured in models with little rotation.

These advantages are highly valued by all customers in our markets, who can have any existing abrasive disc or sheet model with a fast delivery time, as well as with quantities adjusted to their needs.

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)