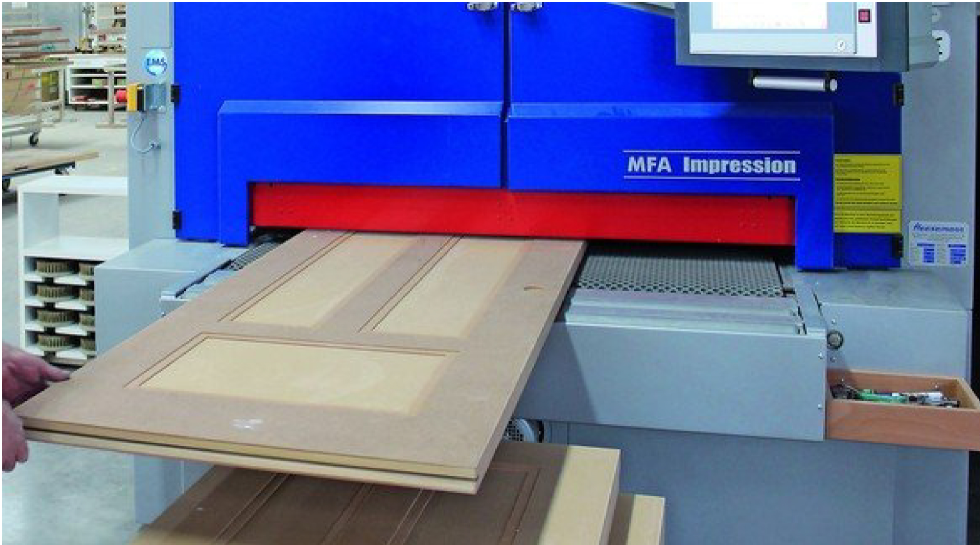

El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}Increasing investment in research and development in the multi-purpose materials industry provides constant innovation within the industry. One of the most important in recent years, due to its performance, is a solid surface, an ideal material to carry out both interior and exterior design of great design and originality.

All this, in combination with a series of properties that make it one of the most innovative and advanced new generation materials on the market. Next, we will know what the solid surface is, its main characteristics and what it is necessary to know about its treatment.

What is the solid surface made of?

The solid surface is made up of two-thirds of natural mineral fillers, which can be silica, quartz, marble or aluminum trihydroxide, among others, and one-third of a series of highly resistant resins, either acrylic. or with a polyester base. This composition gives it an appearance that is pleasant to the touch, reminiscent of natural stone.

Its physical properties make it stand out for its long useful life even under intensive use, for its high resistance and extreme hardness. It does not require maintenance and has a series of characteristics that make it ideal to be used in homes, especially in kitchens and bathrooms, such as being hypoallergenic and antibacterial, being easily cleaned and lacking both pores and joints, something that contributes to the hygiene when handling food on it. Finally, it is considered ecological, both because of the criteria used to manufacture it (without emission of volatile compounds) and because it can be completely recycled.

Regarding the aesthetic aspect, the solid surface offers infinite decorative possibilities, since it can take all the forms that are desired. Along with this, they can be printed on its surface, so that designers and decorators can use it to differentiate spaces, create environments, etc. To all this must be added an extraordinary facility if it had to be repaired.

What applications does the solid surface have?

Although its most popular use for the general public may be the one that we can find in a solid surface kitchen countertop, this material, which is sometimes called 'Corian material' or “Silestone” in reference to this brand, is also used for the manufacture and design of sanitary ware, for floors, for all types of interior furniture and facade cladding.

In the latter case, a special advantage is taken of the fact that it is a material that is manufactured without pores or joints, which helps the thermal and acoustic insulation of homes, helping to make heating and cooling systems more efficient and save on energy bills each month. On the other hand, it is a non-combustible material, which reinforces the safety of the rest of the components that it surrounds.

The solid surface material complies with the UNE-EN 1186-3: 2002 standard, which determines the specifications that materials and articles that are in contact with food products must meet. On the other hand, the international standard ISO19712 establishes the properties of the solid surface material that stands out as resistance to heat, water, impact, thermal shock, chemical products and burns.

Treatments: from die-cutting to material improvements

A solid surface is a type of material that supports various types of treatments. As for the design, it can be die-cut, something that increases its already wide aesthetic possibilities. It admits very diverse forms, the reason why decorative forms can be adopted for very different places, like bedrooms or hallways. On the other hand, it can be backlit and allow the passage of the amount of light you want depending on the design you are looking for.

Regarding the compositions of the material, at this moment we are working on carrying out treatments to improve the formulations, optimize the properties or replace some components with others. Improving the manufacturing process, in which injection and compaction work are carried out, is another permanent challenge.

All this, in order to obtain an even more efficient material, with a series of even better benefits, without forgetting the importance of environmental sustainability throughout its long useful life.

Discover more news and products from the sector like this one at Abracom.

.png)

.jpg)