El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}In this article we will see what are the abrasive bands and all the details of them, to learn to select the ones that best suit our purposes.

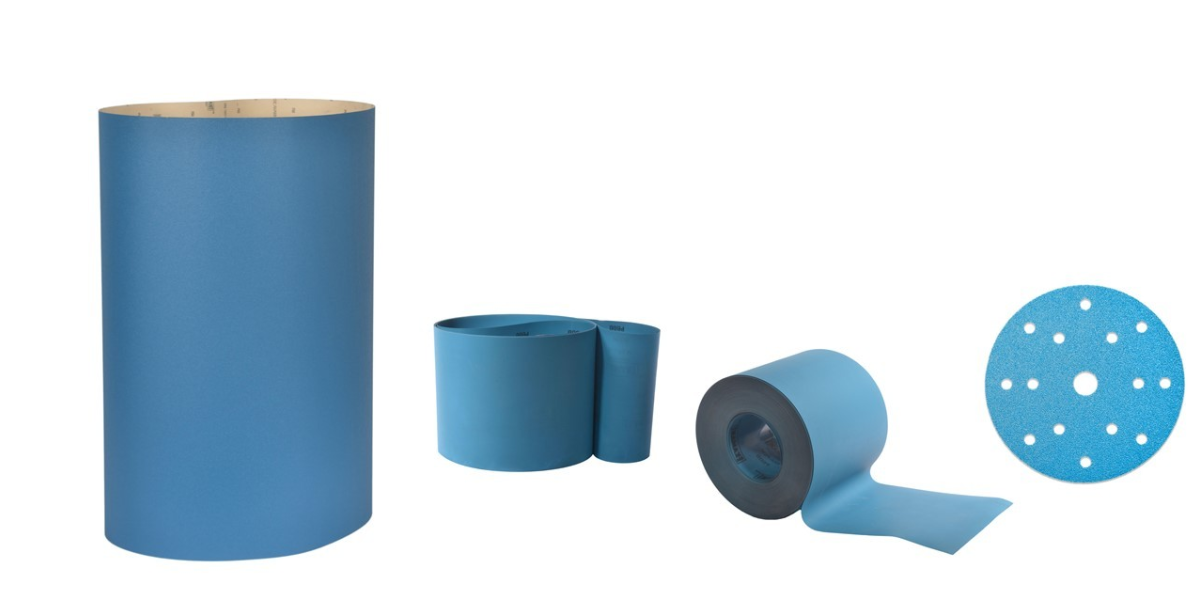

What are abrasive bands?

Abrasive bands are endless bands of an abrasive, applied on a cloth or paper support. They are tapes that are manufactured to the required size and whose dimensions are the width and length of the tape.

The raw material of origin consists of a coil or jumbo roll of abrasive material, which is cut into strips to the desired length and width.

Subsequently, the two ends of the strip join together forming a perfect joint through a manufacturing process that includes the shelling, sanding, gluing and pressing of both parts.

The result is an endless band whose joint has the same thickness as the rest of the belt, and which is capable of withstanding the tensile stresses and the stresses to which it will be subjected during sanding operations.

The raw material is an abrasive manufactured using high technology in which the abrasive minerals are oriented and prefixed on a support by the action of an electrostatic field. Therefore abrasive belts should be considered a sensitive, precision tool.

What are abrasive belts used for?

Abrasive belts are involved in the main industrial processes of surface treatment and finishing, which require a previous sanding operation.

Its field of action is very diverse and covers all types of pieces, sizes, shapes and materials: metals, glass, wood, boards, varnish, rubber, composites, parquet, etc...

Advantages of the bands compared to other types of abrasives

In comparison with the rest of abrasive tools intended for the same use, generally for more manual use, abrasive belts have a number of advantages:

They allow greater performance in sanding jobs, both in time and in production costs

They are used in different models of fixed bench machines that allow from a manual use, to semi-automatic or completely autonomous machines, as is the case with robots with articulated arms that process thousands of pieces throughout the day, maintaining a quality level Optimal as far as surface finish is concerned.

Types of abrasive bands

Although there are no official standards to classify the types of abrasive bands; We can group them according to the format and/or depending on the type of support.

According to the format

The format of the band is defined by its dimensions, that is to say by its width and length. They are classified in:

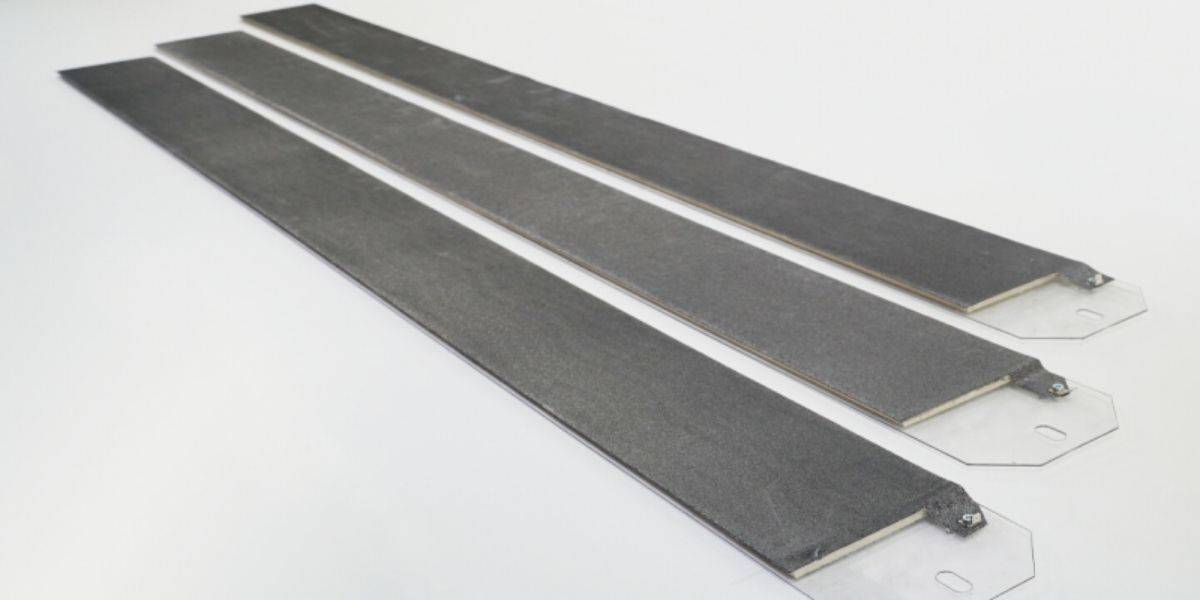

Rings or sleeves (small band shaped ring or gray)

Mini bands (band length less than 690 mm)

Short bands (band length from 690 mm to 3,000 mm)

Long bands (band length from 3.001 mm)

Wide bands (band width from 300 mm and up to 1,600 mm)

Segmented bands (band width from 1,600 mm)

Depending on the type of support

The type of abrasive belt support is defined by the base material used, and on which the abrasive mineral is subsequently fixed by several layers of resins. We can group them into:

Flexible paper bands (paper with weights between 111 and 135 gr / m2)

Rigid paper bands (paper with weights between 221 and 350 gr / m2)

Film bands (polyester film)

Flexible fabric bands (cotton fabrics)

Semi-flexible fabric bands (cotton and polyester fabrics)

Rigid fabric bands (cotton and polyester fabrics)

Very rigid fabric bands (polyester fabrics)

Band of non-woven material (open material of nylon fibers)

How long do abrasive bands last?

Although this is a seemingly simple question, the answer is conditioned by a lot of variables that are only known in very few cases. The main factors that condition the duration of an abrasive tape are:

Different levels of quality in the sanded material: either due to lack of regularity within the same batch or due to differences in quality in the raw material served by different suppliers.

Not recommended use of abrasive belt. For example, when the same belts are used within a specific sanding process to reprocess the parts that have come out defective.

Ignorance of abrasive capacities. For example, when the selected granulometry is required a greater starting capacity than it can generate.

Poor condition of the pieces: being out of initial measurement and / or having surface defects that can prematurely emboss abrasive tapes.

Bad conservation of abrasive belts before being used.

Bad placement of the bands in the machine that ends up causing irregular wear or breakage.

A bad choice of pressure and working speeds.

Poor grain scaling that causes grain breaks to the detriment of progressive and uniform wear.

Care and precautions on abrasive belts

Abrasive belts should be treated with care and caution to avoid breakage and/or surface damage on them that can move to sanded surfaces. They should be treated as a sensitive, precision tool.

Band Storage Precautions

In certain sectors, the support of the bands is generally paper, which is formed by multiple pressed layers of cellulose, which by its nature is hygroscopic and sensitive to atmospheric changes.

The variations of humidity in the day to day directly affect the stability of the abrasive material:

High humidity results in the bowing out of the side edges of the abrasive belt, causing unexpected stops of the contact sander when the band comes out and activates the emergency brake.

the contrary, a low humidity excessively dries the binder of the abrasive tape and makes the material brittle. In addition, the edges of the band are curved inwardly causing unexpected breakage.

A series of cautions are listed below so that the storage conditions are as favorable as possible.

Keep the bands in their original packaging until a few days before they will be used.

Open the box or packaging only when it will be used.

The correct storage temperature is between 18 and 22 degrees.

The recommended relative humidity is between 45 and 65%.

Do not store the boxes near a heat source or window where the material is exposed to the sun. Neither in heights or storage areas near roofs or roofs.

Do not store the boxes directly on stone soils, cement or concrete floors that can easily transmit moisture. Nor near vents, walls or hatches of wells, pits and water pipes.

Do not stack open boxes horizontally, avoiding crushing and deformation of the interior bands.

Tapes handling care

Hang the bands on the appropriate supports so that the band recovers its initial form, free of undulations and vices caused during its permanence in the original packaging.

Prevent bands from hanging near the ground, a cold wall or a heat source. Also prevent them from rubbing each other.

Do not expose the bands to sudden changes in temperature and air currents.

Do not expose the bands directly to sunlight.

Always use the oldest material. The adhesives used in the manufacture of the joint can lose their properties from the year of seniority.

Take special care when handling the bands when removing them from the box, placing and/or taking them from the hanger, placing them and / or removing them from the contact sander (never do these actions with the suction system on), leave them temporarily in the ground outside the contact sander (prevent them from losing their balance and can fall on objects that damage them)

Why choose Abracom abrasive belts

Abracom is a manufacturer highly specialized in the production and marketing of all types of abrasive belts for the industry. We manufacture custom bands and we do it in maximum 48 hours. We have the specific abrasive for each material and sanding operation. We have new, very flexible machinery and close and decisive team of professionals.

Contact us and we will help you.

.png)

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)