El lijado de superficies planas barnizadas es una operación habitual en la industria de la madera, los tableros y la...

}The glass surfaces bring elegance to any room and at the same time are a perfect solution to take advantage of the space, as they contribute to generating a feeling of spaciousness. However, its maintenance must be periodic so that its properties are preserved intact. Glass polishing serves to eliminate defects that have formed on the surface, such as scratches, scratches or pitting, and restore its original transparency and brightness. If you want to know how to polish glass, we offer below the indications about the process that you must follow.

Polishing glass serves to eliminate surface defects and restore its original transparency and brightness

How to polish glass step by step

The process of polishing the glass is not complex, but the steps to follow to achieve an optimal finish should be known.

first step: cleaning. For a good result it is essential to clean the surface in detail to remove dirt and, in addition, to be able to locate the scratches or scratches that we want to remove with polishing

Second step: first sanding. With the help of a radial polisher and an abrasive disk of 150 or 180 grain, with silicon carbide ore, perform a first sanding until the defect has been physically removed. For this we use the finest sandpaper grain that can eliminate the defect. It is important that this process be done on the glass surface, avoiding sanding with the edge of the discs. We must also make sure that during the glass polishing work, the glass does not overheat, which is

equivalent to saying that it does not exceed 65 ° C.Third step: advanced sanding. Then we will repeat the previous step in a staggered way, but this time using other abrasive grains: 240, 320 and 400

Fourth step: the nuance. With the help of a disc with sponge support, soft finish discs, in 400 or 500 grain, we will make a sanding of matting, to get the scratched surface to integrate with the surface without sanding. At all times we must control the temperature of the

glass. Repeat this process with grain 600 and then with grain 1,000. As we refine the surface the stripes caused by sanding are smaller and finer, and the surface acquires a more translucent appearance.Fifth step: polishing. Once the repaired surface and the surrounding areas are nuanced, we will proceed to polish it. For this we will use a velcro disc of felt and abrasive paste capable of eliminating the scratches generated by the 1,000 grain. During the polishing process

we must ensure that the glass does not get too hot. For this reason we will work with low revolutions (between 900 and 1,400 rpm) Then we will clean the surface and perform this step successively until we make sure that the surface is completely finished.You may be interested: Hand sanders: types and uses of portable machines

Characteristics of glass and glass polishing

Polishing glass and tempered glass differs from polishing other materials in that the entire

process (sanding and polishing) must be performed with a machine with radial movement

(polisher). In other sanding-polishing processes the initial sanding steps are performed with a

sander with a roto-orbital movement. Temperature control is a key factor when it comes to

polishing glass, unlike other materials in which this factor is not so critical.What tools are used to polish glass

Microfiber dishcloth for cleaning and silicone-free cleaning liquid, which is used in the

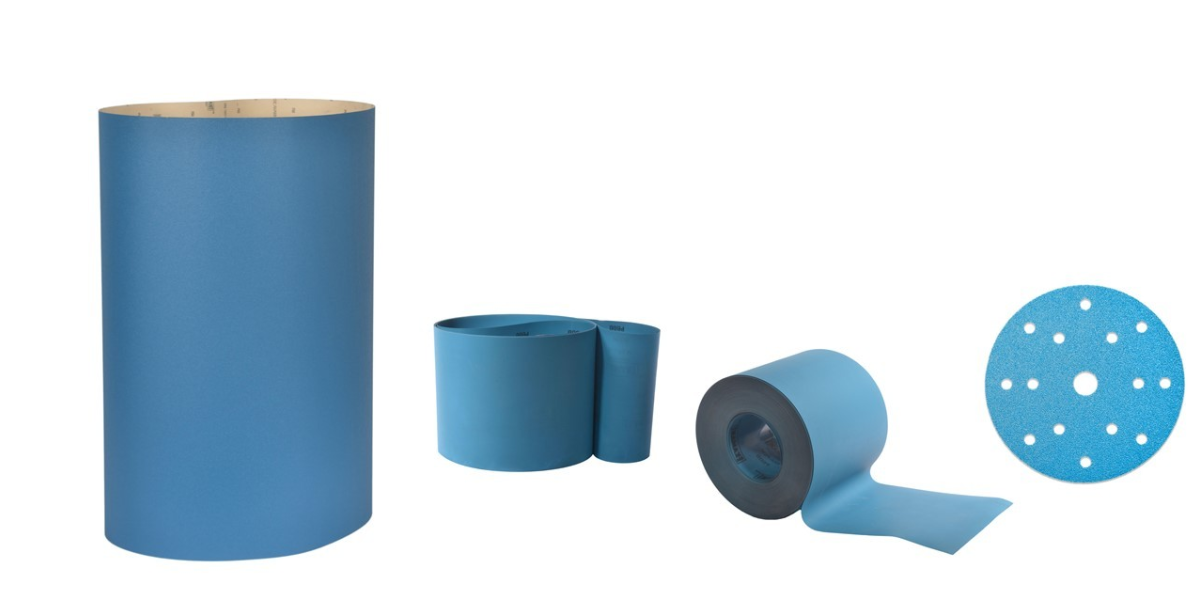

first step of the process.Electric polisher and velcro discs, D150 mm, with paper support and with silicon

carbide ore (grains 150, 180, 240, 320 and 400). They are used both in the first sanding

and in the advanced sandingElectric polisher and velcro discs, D150 mm, with sponge support and with silicon

carbide ore (500,600, 800 and 1,000 grains). This tool is used during shading.Electric polisher, felt velcro disc and polishing paste capable of removing 1,000 grain

scratches, all for the surface polishing process.

Products for polishing glass: features and tips

The abrasive products for polishing glass are basically three:

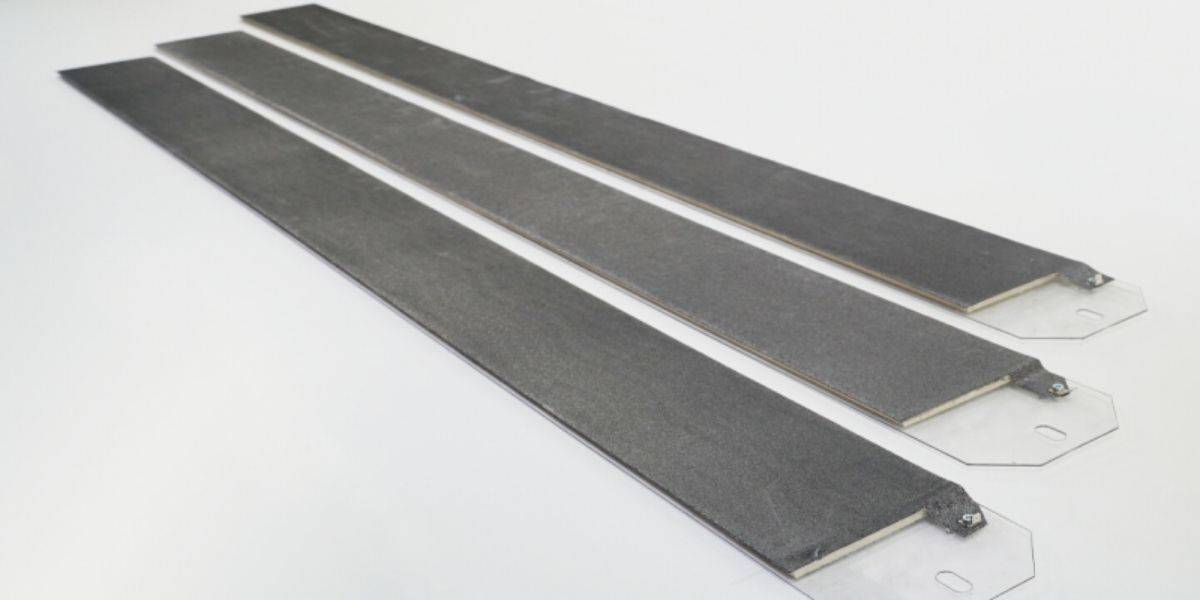

Velcro abrasive disc, D150 mm, with silicon carbide paper and mineral support.

Velcro abrasive disc, D150 mm, with sponge support and silicon carbide mineral.

Polishing paste, silicone free, capable of removing scratches from 1000 grit.

It is vital that the abrasives used are made of silicon carbide ore. The hardness of this mineral

is only surpassed by the diamond, its edges are very sharp and its high friability (ability to

break under a certain pressure creating new edges) make it ideal for sanding hard surfaces

that need a shallow scratch and very uniform (to minimize changes in the refraction of the

light that passes through them).Tips for proper glass polishing:

The main one is to follow in detail all the steps described above, dedicating the

necessary time to each operation.In reference to safety, it is necessary to wear eye protection goggles and nasal mask to

prevent the fine dust generated from glass can damage the eye and respiratory tract.Why Abracom is the best guarantee of a perfect glass polish

Abrasive discs are the main product used to repair glass surfaces. Abracom is a manufacturer specialized in this sector since it imports and dies jumbo rolls of sandpaper with velcro to transform them into abrasive discs.

In addition, it has a very wide range of abrasives with different supports: flexible, rigid papers,sponge, film, abrasive mesh; and with different types of ore, including silicon carbide. And finally, Abracom is a fast, flexible and competitive supplier for all levels of consumption, which

makes it the perfect ally to achieve the best glass polishing.Do you want to know more about the options for polishing glass and/or other materials available at Abracom? Contact us and we will advise you.

.png)

(1).png)

(1).png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)

.png)